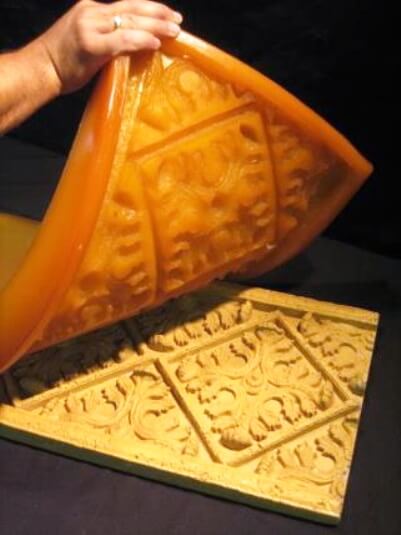

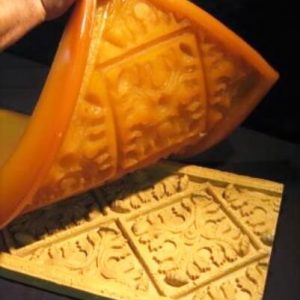

- Soft to Mid- Range Hardness (Poly 74 Series) used for simple to Highly Detailed Undercuts and Complex Moulds for Casting Precast Concrete, GRC, Plaster, Art Foundaries, Sculpture & Décor Reproduction

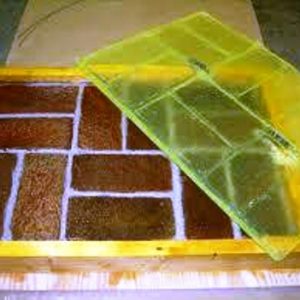

- Mid-Range to Firm Hardness (Poly 75, 77 Series) used for making Moulds to cast Precast Concrete Pavers, Slabs, Retaining Walls, Flexible Formliners, Concrete Countertops, Architectural GRC, Concrete Stamping Tools and Skins

- Firm Hardness (Poly 81 Series) used for making Moulds, Mould Facings, Stamping Tools, Industrial Parts, Rollers, Gaskets, Bumpers, Pads etc.

These polyurethane mold rubbers span the range of very soft (A20) to very firm (D45) rubbers which, when mixed as supplied, can be used to create a multitude of poured molds and flexible parts.

These two-part liquid rubbers are excellent choices for making molds for casting concrete, plaster, wax as well as for limited resin and foam casting applications.

The Poly 74-Series rubbers are soft to mid-range hardness rubbers (A20-A55) and can also be thickened with Fumed Silica or Poly Fiber II to create brushed molds.

Poly 75 & 77-Series rubbers are mid-range to firm rubbers (A60-A90) and Poly 81-Series systems are even firmer (A90 to D45).

Pourable Polyurethane Mold Rubber Series |

|

| Poly 74-Series | Shore A20 to A55 hardness liquid mold rubbers. High-strength, abrasion resistant, longest lasting molds. Economical & versatile. |

| Poly 75-Series | Shore A60 to A80 hardness liquid mold rubbers. High-strength, abrasion-resistant, super-tough rubbers. Lng lasting & economical. |

| Poly 77-Series | Shore A50 and A65 hardness liquid mold rubbers. High-strength, abrasion-resistant, high elongation rubbers. Lower viscosity compared to other rubbers at A50 & A65 hardness. |

| Poly 81-Series | Shore A90 and D45 hardness liquid rubbers. Great for creating durable mods, mold facings, stamping tools, industrial parts, rollers, gaskets, mold shells, bumpers, pads and much more. |