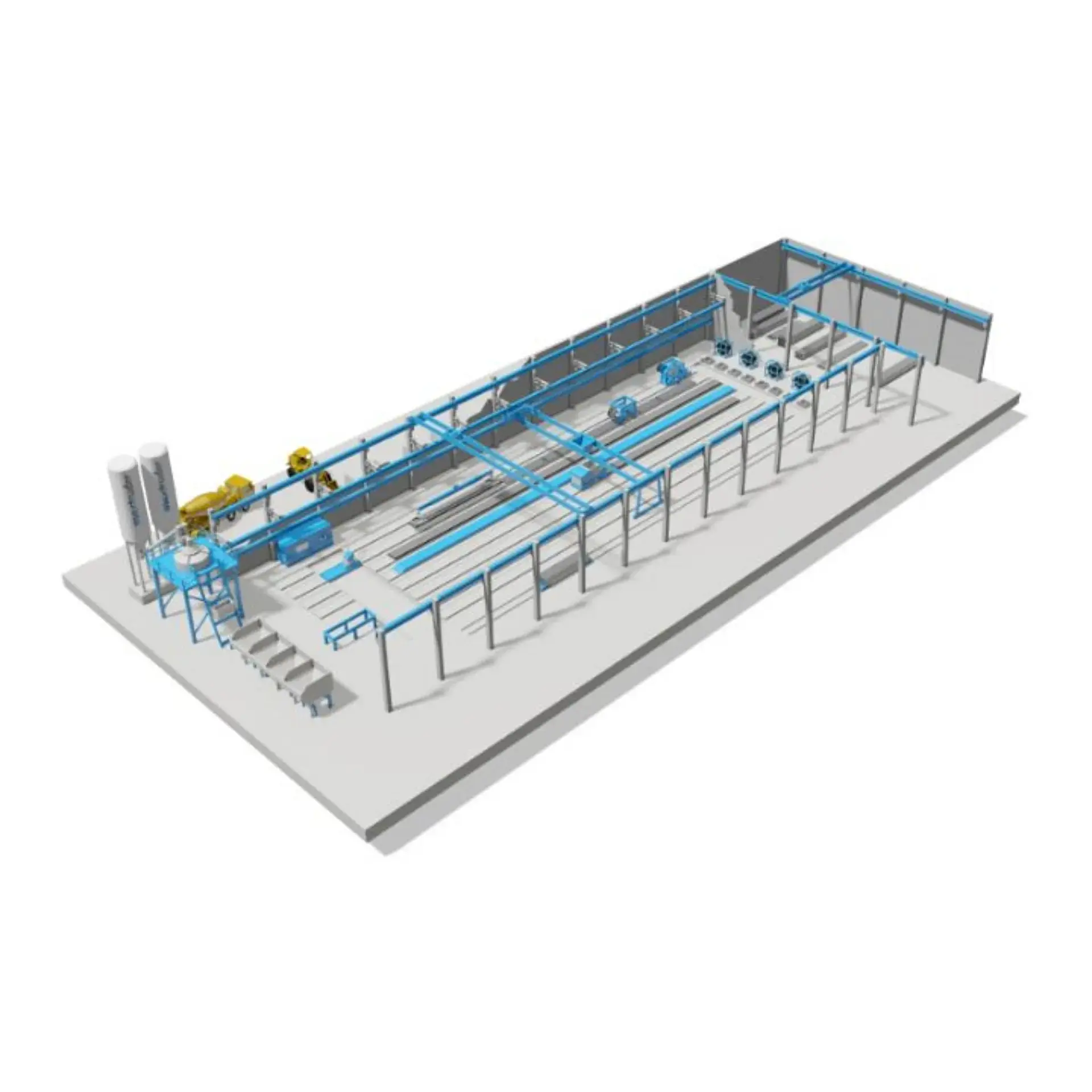

Stationary Precast Concrete Factory

Maximum output with minimum operating costs enable short-term return on investment

Modular, scalable stationary production technology ensures optimal precast production with maximum output. Low running costs and the highest quality end products permit a short-term return on investment. Our modular system allows easy conversions, retrofits and upgrades, for example in capacity, product range, degree of automation. A highly automated precast plant starting from the concrete mixing plant to the concrete transport to the production machine avoids manual errors. Applied industrial procedures ensure highly efficient production. The enormous cement savings and minimal water consumption of our hollow core slab production modules enable further efficiency increases in two- or three-shift operation.

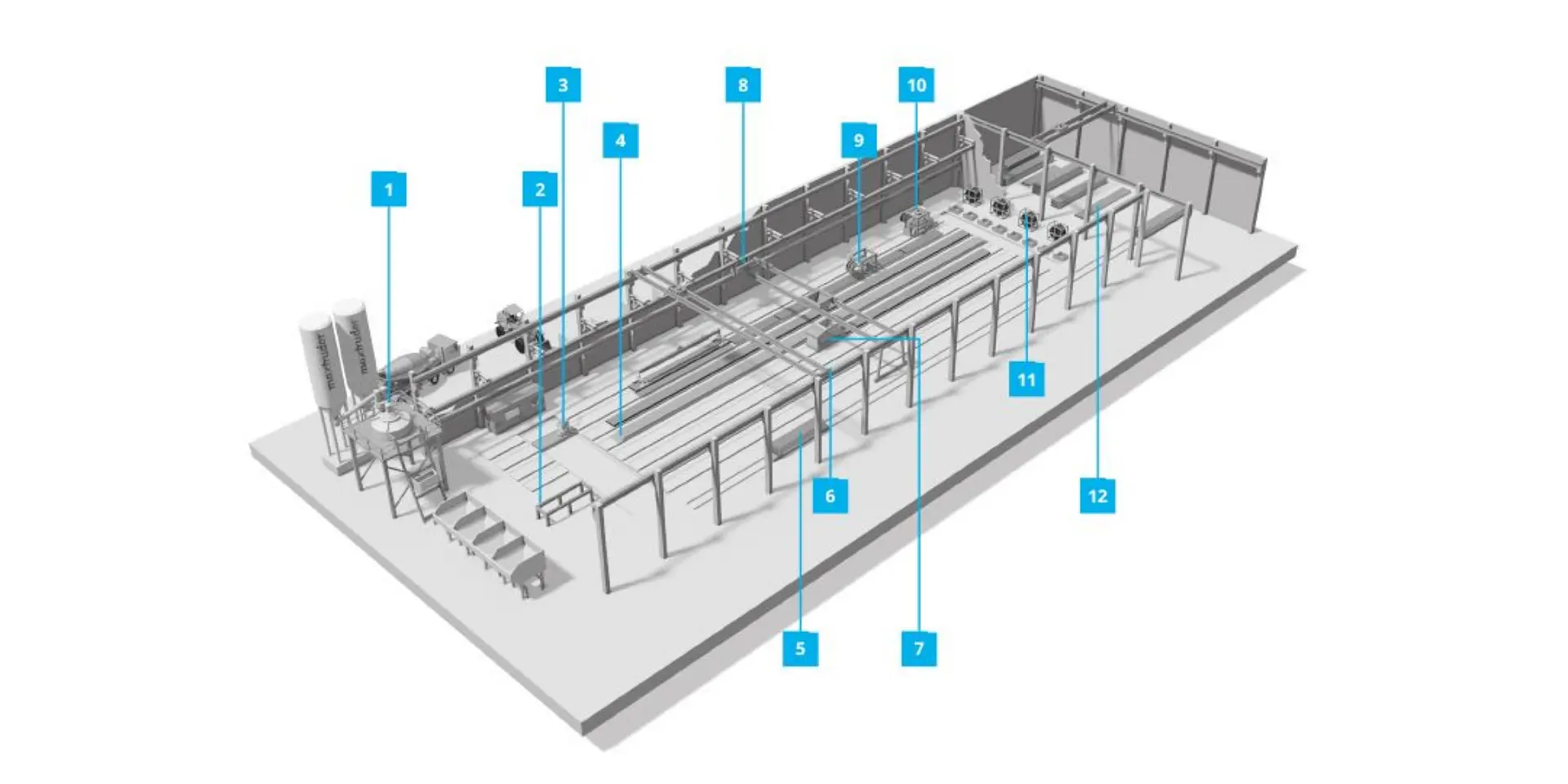

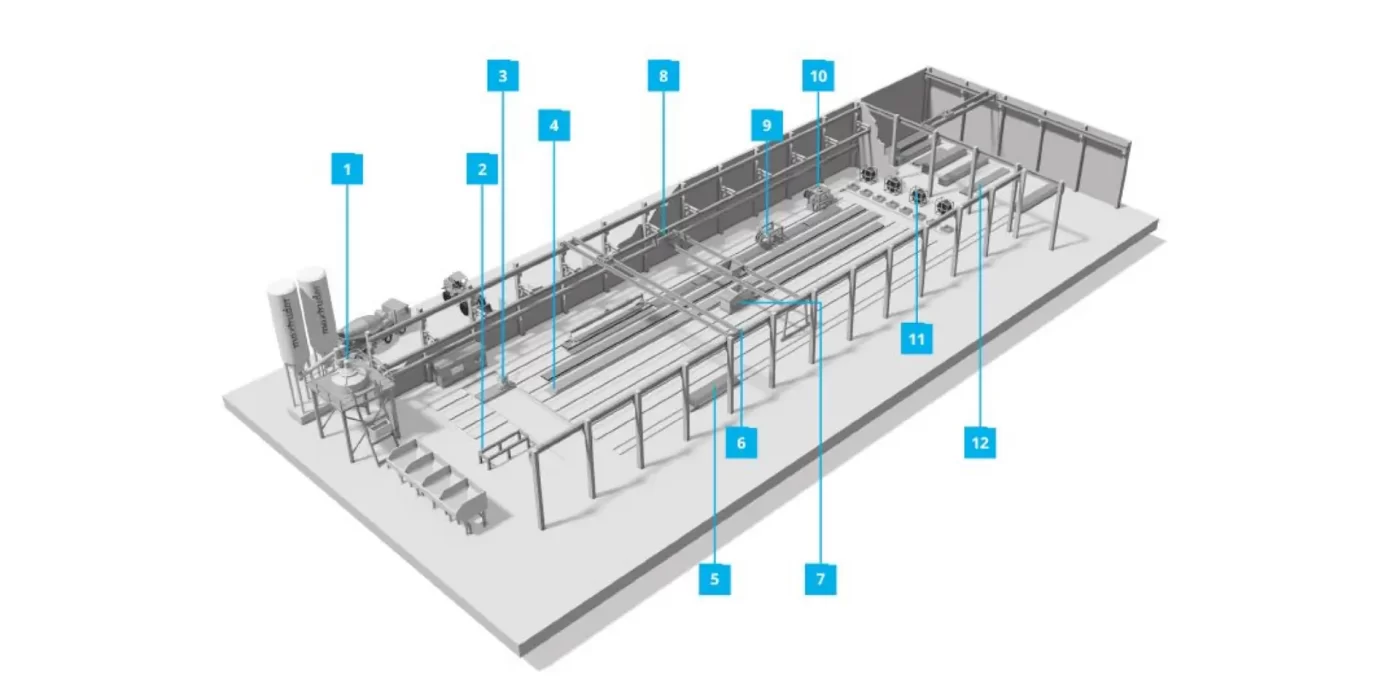

TYPICAL MODULES OF A STATIONARY PLANT

| 1 | Batching Plant | Univeral and powerful |

| 2 | Maintenance Area | Reliable, user-friendly |

| 3 | Pre- and post tensioning area | Safety, precision, accuracy |

| 4 | Production beds | Shortest curing time, resonance free |

| 5 | Transport systems for finished products | Efficient factory logistics |

| 6 | Over head crane | Various tasks |

| 7 | maxtruder / maxcaster | Strongest hollow core slabs, wall elements and more |

| 8 | Automatic concrete supply | Fast, safe |

| 9 | Concrete saw | Extended saw blade lifetime |

| 10 | Preparation machine | Cleaning, oiling, wire pulling |

| 11 | Stressing wire decoiling reel | Efficient and reliable |

| 12 | Storage area | Project specific |

Typical products for a mobile precast factory

COST-OPTIMAL PRODUCTION

- Modular design: Initial investment, productivity and return on investment tailored to your needs

- Capacity scalable, automation level and product range expandable

- Highly reliable, wear-resistant components, reduced production costs

- Hollow slab production without chemical concrete admixtures

MAXIMUM PRODUCTIVITY

- Automation scalable to suit for increasing productivity and reducing labour costs

- Long line bed production with shortest curing times allow daily double occupancy

- Enhanced system configuration and process modelling, reduced changeover times

HIGH-QUALITY FINISHED CONCRETE PRODUCTS

- Efficient industrial procedures guarantee constantly high quality of the precast concrete products

- Long bed production with highest compaction for concrete strengths up to 90 MPa and perfect stressing wire adhesion

- Accurate concrete products, ready for painting ex works

EXAMPLE OF A STATIONARY PRODUCTION PLANT IN FIGURES:

| Theoretical capacity | 288 – 1.150 m²/day | 86.400 – 354.000 m²/year (Single shift operation) |

| 576 – 2.300 m²/day | 172.800 – 690.000 m²/year (Double shift operation) | |

| Worker | 8 |

| Production area | 3.500 m² |

| Site area | 7.000 m² |

| Number of production beds | 2 – 8 |

| Max. hollow core slab thickness / length | 400 mm / 20 m |