Mobile Precast Factory

Well-targeted entry into the precast concrete industry with low initial investment and maximum flexibility

A mobile modular, scalable precast concrete plant offers entirely new possibilities for the production of high-quality precast concrete parts on site. The advantages in quote calculation for large projects will also be attractive. A mobile plant enables you in offering high-quality precast concrete parts at best flexibility with minimum transport costs. The location-independence of the facility gives you a clear competitive advantage in project tenders; with on-site production even eliminating the need to invest in a suitable plot of land.

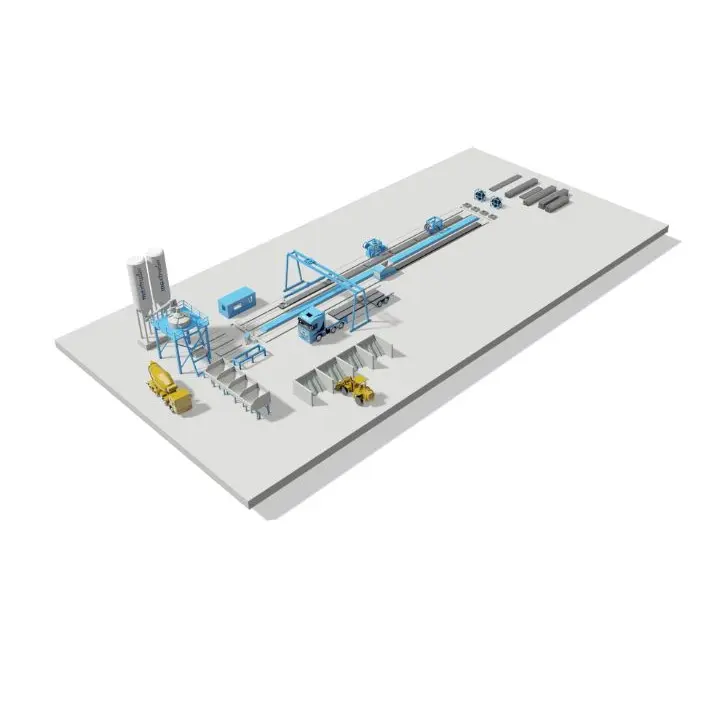

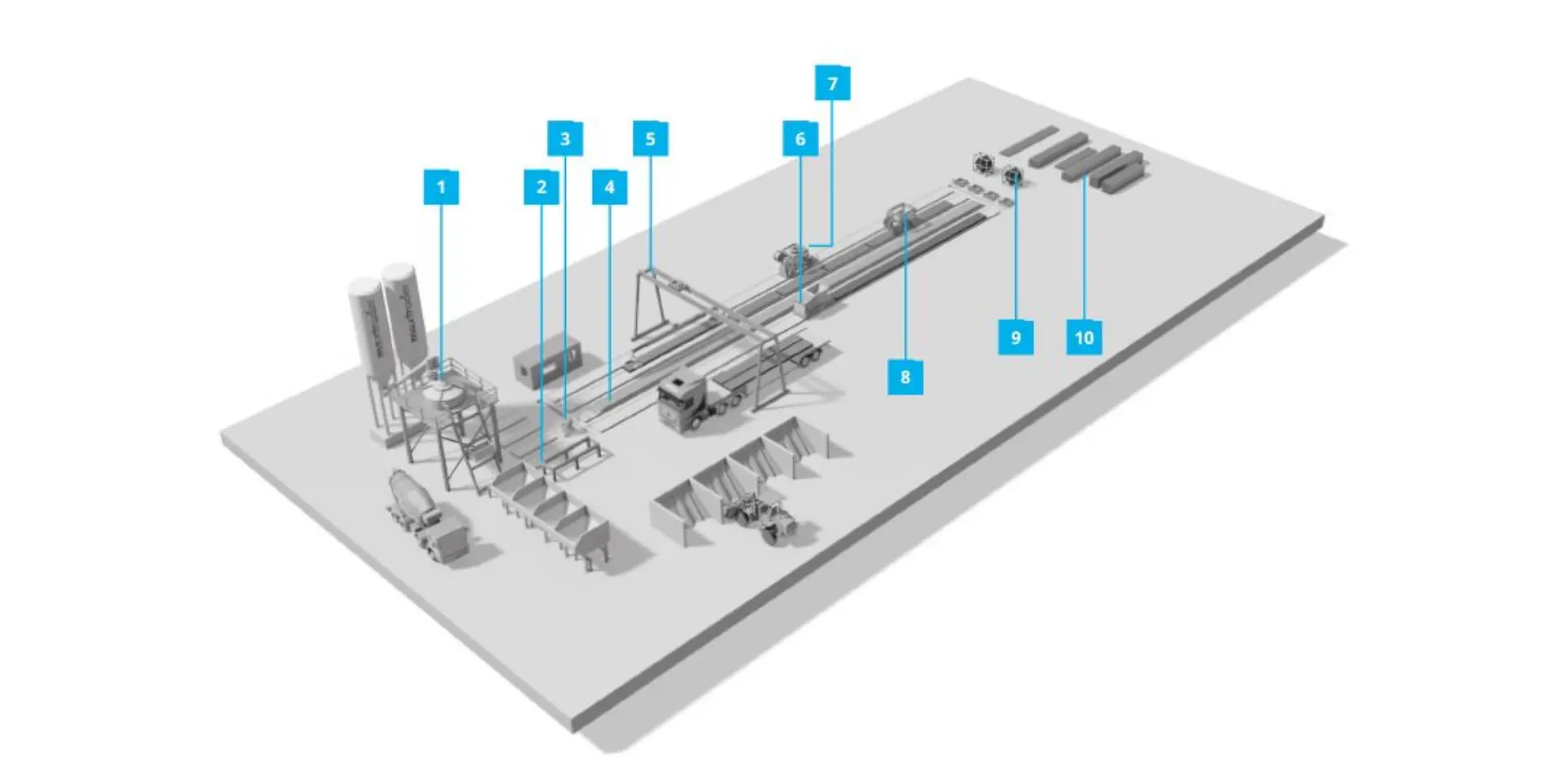

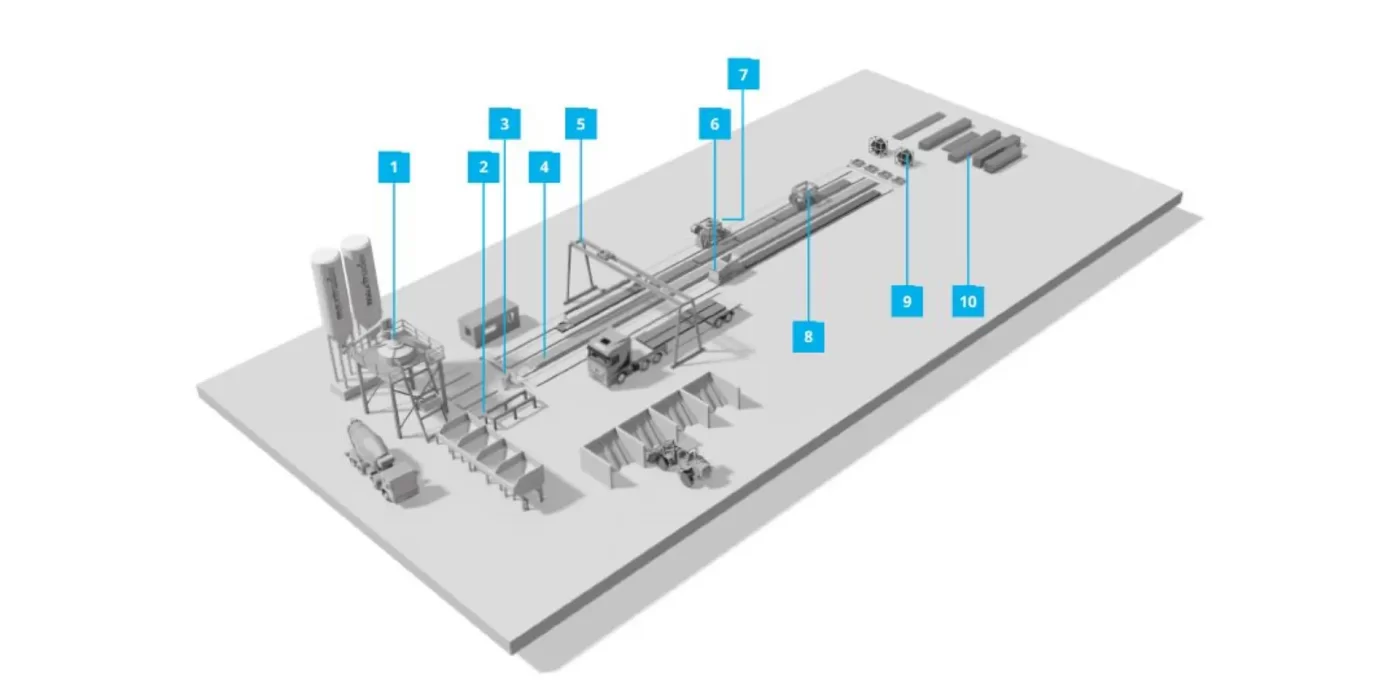

TYPICAL MODULES OF A MOBILE PLANT

| 1 | Batching Plant | Universal and powerful |

| 2 | Maintenance Area | Reliable, user-friendly |

| 3 | Pre- and post tensioning area | Safety, precision, accuracy |

| 4 | Production beds | Shortest curing time, resonance free |

| 5 | Gantry crane | Various tasks |

| 6 | maxtruder / maxcaster | Stongest hollow core slabs, wall elements and more |

| 7 | Preparation machine | Cleaning, oiling, wire pulling |

| 8 | Concrete saw | Extended saw blade lifetime |

| 9 | Stessing wire decoiling reel | Efficient and reliable |

| 10 | Storage area | Project specific |

Typical products for a mobile precast factory

COST EFFECTIVE PRODUCTION

- Low initial investment in production equipment and premises

- Just in time production and shortest supply chains

- Savings in raw materials and labour time

- Hollow core slab production without chemical concrete admixes

HIGHEST FLEXIBILITY

- Particularly fast installation and commissioning

- Rapid relocation of the production plant to another site

- Wide range of modules for flexible production of various prestressed/reinforced components

HIGH-QUALITY FINISHED CONCRETE PRODUCTS

- Efficient industrial procedures guarantee constantly high quality of the precast concrete products

- Long bed production with highest compaction for concrete strengths above 75 MPa and perfect stressing wire adhesion

- Accurate concrete products, ready for painting ex works

EXAMPLE OF A MOBILE PRODUCTION PLANT IN FIGURES:

| Theoretical capacity | 144 – 576 m²/day | 43.200 – 172.800 m²/year |

| Worker | 10 |

| Production area | 2.000 m² |

| Site Area | 3.500 m² |

| Number of production beds | 1 – 4 |

| Max. hollow core slab thickness / length | 320 mm / 15 m |

| Duration until 1st production | 4 weeks |